Popco at Shop Marketplace: A smash success!

hello Cincinnati... On Tuesday, April 9, two Popconians landed at the CVG airport in northeastern Kentucky and made their way directly to the Duke Energy Center in Cincinnati, just a short drive across the Ohio river and the Kentucky/Ohio border. There, they set up a...

Popco rocks the Shop! Marketplace show

Hello Cincinnati! Popco is on the road and ready to rock the 2024 Shop! Marketplace trade show. Show dates are April 9 - 11, 2024 and the venue is the Duke Energy Convention Center in Cincinnati, Ohio. In the words of the show organizers, "Shop! MarketPlace is the...

One part & three ways to display

We’ve built a better mousetrap... Well, not so much a better mouse trap, more like a better mouse-trap tool. Specifically, we’ve built a multi-cavity, injection-molded tool that produces (16) pieces of our three-way sign holder with each pass on our machines. To put...

Popco has the tools for the job

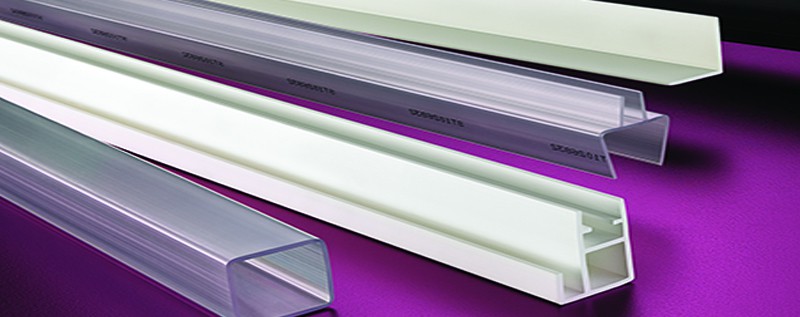

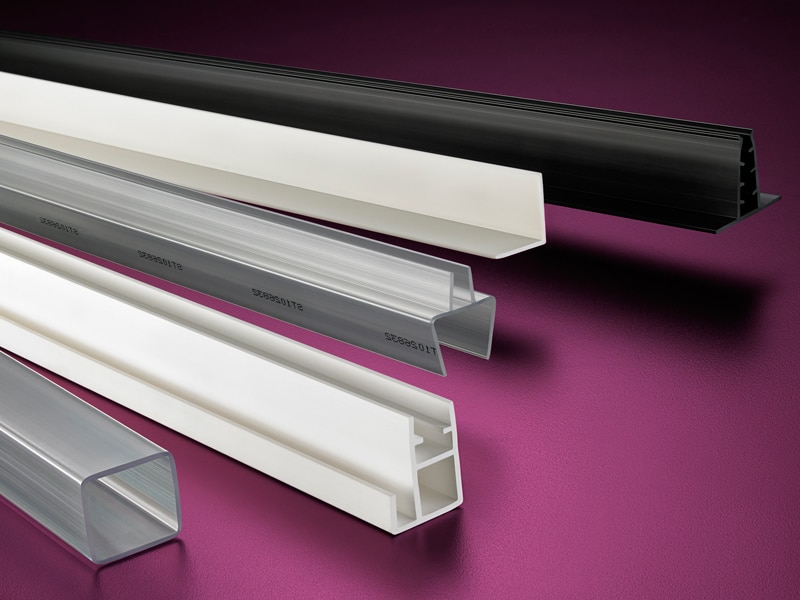

At Popco, we’re tickled pink... Tickled pink about a huge new addition to our website. We’re talking about our upgraded custom-tools section that now includes hundreds of extruded profiles for which we have production tools. These profiles, designed to serve the...

Happy holidays from Popco

It's that time of year again. The time when we reflect on a year that's nearly past and look forward to the new year ahead and all of its possibilities. Once again, we find ourselves grateful for all of the support that we've received from our customers and our...

Clip, Clip, Done!

Choose a favorite adjective and it’ll likely apply to Popco’s squeeze-clip sign holders. Here are some modest suggestions: Simple, straight-forward, versatile and practical. Or, if you’d prefer, some more extravagant suggestions are: spectacular, outstanding,...

Popco helps you through thick and thin

“One size fits all” is such a lovely notion. Too bad it’s rarely true without compromise. For...

Popco sign bases are cooler than you think

Popco’s sign feet are primarily used to support signs on counters, shelf tops and end caps, but...

Hook up and save with Popco

discounted wire hooks Wire hooks, double C-hooks, ceiling display hooks; whatever you call them,...

Popco’s steel looped cable & universal banner clip

Popco’s steel looped cables are ideal for hanging signs at fixed heights. The cables are very...

Popco offers magnetic attraction

For a simple, elegant and robust means of displaying signs on metal surfaces, you can’t beat...

Popco launches a new website

Welcome to the first installment of Popco’s new blog and welcome to our new and, we believe,...

Popco suction cups with screws for wall-mounting

A customer has shared with us a unique use of our suction cups that we are really excited about....

More foam board products from Popco

In our last post, we spoke about our foam board edge protector. In this post, we’ll continue the...

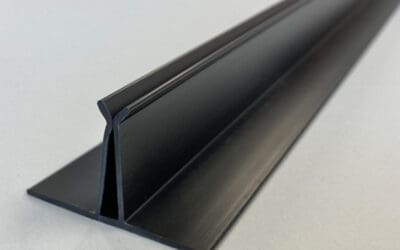

Popco foam board edge-protector

Foam board is a terrific material for retail signage. It’s light, making it practical to ship and...

BPA, phthalates and other fishy things

Among the most curious questions asked by a Popco customer was if our suction cups included BPA....

Kudos for Popco’s president

At Popco, we're very proud that our president, Elihu Wear, has been honored by Fortune Magazine in...

Swatch you lookin’ at?

At Popco, we pride ourselves on practicality. We ought to since we are purveyors of widgets that...